| Material | Ti6AI4V (Gr.5) Titanium |

| Thread size | M14 × 1.5 mm (Compatible with Most Aftermarket Wheels) |

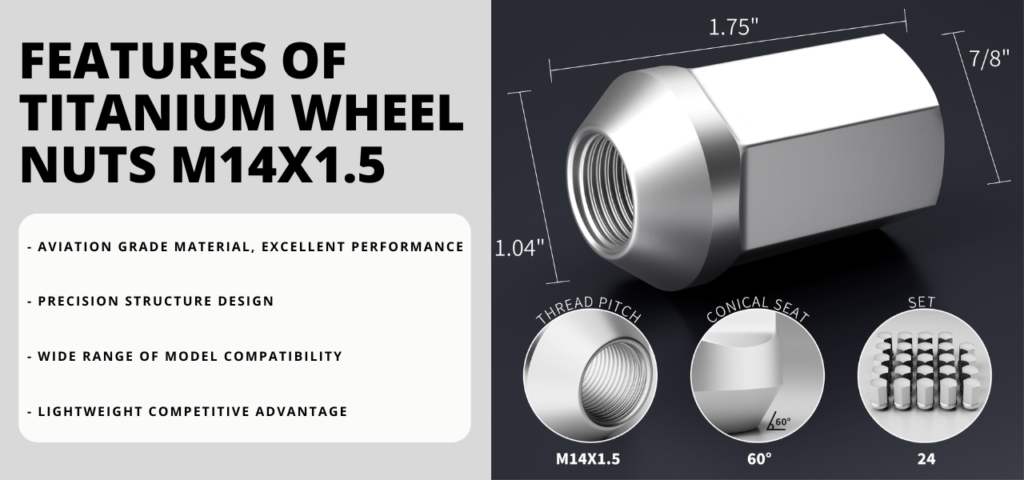

| Size | 7/8″(22mm)hex / 1.75″(45mm)length / 1.04″(26.5mm)width |

| Style | 60° conical seat / One-piece conical / Closed end |

| Compatibility | Racing Cars, SUVs, Trucks, Off-Road Vehicles, and Custom Builds |

| Fitment | Replacement for 2011+Dodge Durango, 2011+ Grand Cherokee, 2012+Ram 1500 2500, 2019+ wrangler, 2019+ gladiator, silverado, tahoe Gmc sierra Suburban Colorado,etc |

| Color | Natural Color/Black/Burnt Blue/Golden/Rainbow/Purple/Green/Customized color |

Categories:Titanium Fasteners, Titanium Hex Head Bolts

Our Titanium Wheel Nuts M14×1.5 mm is precision forged in aero-grade titanium alloy with high strength and lightweight properties for high performance automotive and racing wheel modifications, providing stable torque retention for safe tightening under extreme driving conditions.

Titanium Wheel Nuts M14×1.5 Specs |

|||||||

|---|---|---|---|---|---|---|---|

| Material | Ti6AI4V (Gr.5) Titanium/Custom | Hardness | Rockwell C36 | Customizable Colors | Natural Color/Black/Burnt Blue/Golden/Rainbow/Purple/Green/Customized color | ||

| Thread size | M14×1.5 mm | Quality Control | 100% Fully Check | Vehicle Compatibility | Racing Cars, SUVs, Trucks, Off-Road Vehicles, and Custom Builds | ||

| Size | 22 mm hex 45 mm length 26.5 mm width |

LOGO | Customizable | Fitment | Replacement for 2011+Dodge Durango, 2011+ Grand Cherokee, 2012+Ram 1500 2500, 2019+ wrangler, 2019+ gladiator, silverado, tahoe Gmc sierra Suburban Colorado,etc |

||

| Style | 60° conical seat One-piece conical Closed end |

Surface Treatment | Pickling/Polishing/ Anodizing/PVD Coloring |

MOQ | Items in Stock (China):MOQ 1 PC Items in Stock (USA):MOQ 1 PC Items Out of Stock: MOQ 100 Pieces |

||

The Gr.5 titanium alloy (Ti6Al4V) widely used in the aviation field, with both high strength (tensile strength ≥895 MPa) and lightweight (density only 60% of steel), significantly reduce the unreed mass, improve vehicle acceleration, braking and handling performance.

The 60-degree Conical Seat is closely fitted with the wheel hub contact surface to ensure uniform force distribution and prevent loosening; The thread specification of M14×1.5 mm accurately matches the hub bolts of mainstream modified models; 22 mm hexagonal head ADAPTS to standard sleeve tool, easy to install; 45 mm length +26.5 mm width optimized space layout, compatible with a variety of modified wheels and extension bolts requirements.

Widely compatible with 2011 Dodge Durango, Grand Cherokee, Ram series pickup, Wrangler JL/JT, Chevrolet Silverado and other American models, covering more than 90% of the modified wheel hub market, is an ideal upgrade replacement for the original factory steel nuts.

the weight of a single nut is reduced by about 40% compared with steel products of the same specification, and the cumulative weight loss of four wheels can reach 0.5-0.8 kg, which helps to reduce the unreed mass and optimize the suspension response speed and track lap performance.

Gr.5 aviation titanium alloy, weight is only 60% of the steel nut, significantly reduce the unsprung mass, improve vehicle acceleration and control sensitivity; The tensile strength is as high as 1100 MPa, far exceeding that of ordinary steel (about 700 MPa), ensuring tensile and fatigue resistance in extreme track and off-road scenarios.

Closed end design to prevent thread corrosion and dust intrusion, extend service life; The 60-degree conical base seamlessly fits the hub contact surface to avoid stress concentration and prevent the risk of loosening caused by high-speed vibration.

M14×1.5 mm thread specification matches mainstream modified models, covering 2011+ Dodge Durango, Jeep Wrangler, Chevrolet Silverado and other American off-road vehicles and pickups; 45 mm extended thread and 22 mm thickened hexagonal head design, ADAPTS to standard tools and enhances locking force, simplifying installation process.

Through 500 hours of salt spray test, withstand snow, snow melt agent and wet environment, fear long-term outdoor use.

Anodized surface treatment provides black/blue/red color options to meet the needs of personalized modification.

Can do different surface treatment, such as Pickling/Polishing/Anodizing/PVD Coloring, etc.

Non-standard sizes and shapes can be customized according to drawings to meet special wheel lugs or upgrade requirements.

Can be customized Color, such as Natural Color/Black/Burnt Blue/Golden/Rainbow/Purple/Green, etc., to meet customer demand on beauty or logo.

Laser engraving of brand Logo, number, warning.

According to customer packaging requirements and methods, we can provide personalized packaging materials, labels, etc

We have 10 years of experience in the production of titanium wheel nuts, whether it is the design optimization of the product, or the problem solving in the production process, we can rely on the rich experience to quickly make the right decision to ensure the quality of the product and production efficiency.

Customize different specifications, surface treatment and packaging solutions according to customer needs, and the MOQ of customized services is as low as 100 pieces.

Our titanium wheel lug nuts adopt multiple quality control processes, including raw material testing, size testing, performance testing, etc., to ensure that each product can meet customer requirements.

As a direct manufacturer without intermediate traders, we can provide customers with more competitive prices and high-quality products to help you improve vehicle performance.

The production cycle is short, under normal circumstances can be delivered in advance.

A: Replace for 2011+ Dodge Durango, 2011+ Grand Cherokee, 2012+ Ram 1500/2500, 2019+ Wrangler, 2019+ Gladiator, Silverado, Tahoe, GMC Sierra, Suburban, Colorado and other models.

A: Yes,it is easy to install. Standard 7/8″ (22 mm) hexagonal socket can be used for installation without special tools.

A: Titanium alloy has significant advantages over traditional steel, such as lightweight, the weight is only 60% of steel; Tensile strength of 1100 MPa, higher than ordinary steel about 700 MPa; Strong corrosion resistance, suitable for humid, off-road and other harsh environments.

A: The closed structure prevents dust and sand from invading the thread and prolongs the service life. Reduce redundant weight while maintaining overall structural strength.

A: Anodizing treatment provides stable color, which is not easy to fade in daily use. Wipe with a soft cloth dampened with a neutral cleaner to avoid hard objects or strong acid/alkaline solvents.

A: Yes! This titanium wheel nuts is ideal for track or extreme off-road scenarios. Lightweight design improves suspension response and high strength material withstands high frequency vibration. Corrosion resistance and tensile resistance suitable for muddy, gravel and other complex terrain.